KURRE Systems develops powerful control software with improved interface

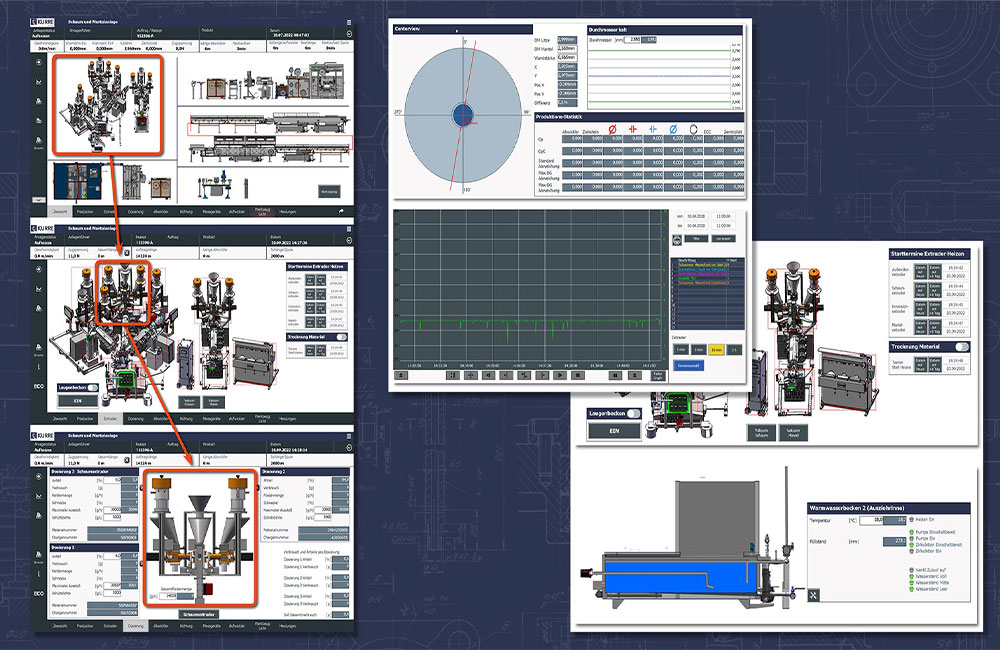

With the completely revised machine control system “KURRE Control & Database System”, the German company KURRE Systems takes a big step towards Industry 4.0. In addition to the outsourcing of computing power with more options for data tracking, the topic of usability and OPC-UA interface also plays a major role.

“The increased computing power in combination with our new WIN CC-based visualisation enables us to document, visualise and optimise processes even more precisely. In this way, the refined man-machine interface enables greater effectiveness of the production facilities,” reports Dennis Veit from the project management at KURRE. The reliefing of the SPS and a corresponding shifting to the high-performance industrial PC (IPC) made this possible.

“The entire data acquisition restructuring improves the products’ quality”, Dennis Veit explains further. The user is supported with numerous analysis tools (e.g. FFT analyses, various process diagrams) and the retracing function of all (raw) materials used. Processes can be monitored, controlled and adjusted live from outside through the additional network connection. Networking with other plants or ERP systems is also possible. In addition, this gives more accurate information in terms of predictive maintenance.

Intuitive operation was the focus of the visualisation concept. The former table-oriented display is replaced by a structured, graphically oriented interface with logical menu navigation. For example, users can virtually click through the machine and adjust the required parameters exactly where these would be found in real. “The new structure makes it easier for operators to maintain an overview and reach their goal more quickly. This significantly reduces the training and operating time,” explains Dennis Veit.

Furthermore, the modular structure of the new control system can be expanded and updated. The basis is the new visualization as well as the networking with the IPC and the resulting data management for an ideal and innovative process control. On request, other modules such as analysis tools, color change systems and the setup module offer options for supplementary support. For example, the setup module provides a customizable instruction that helps to ensure an error-free setup process. An included tablet PC allows the operator an easy and safe setup using predefined checkpoints as well as supporting images and information.