Automation up to the ready-to-ship product

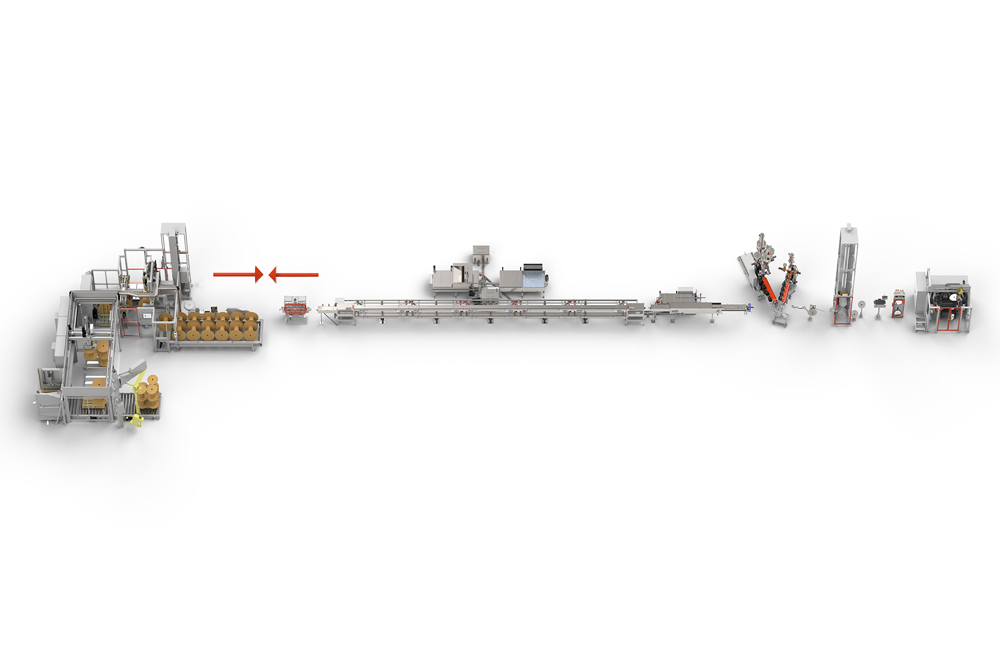

KURRE Systems is launching a Maxi line with a new optimized interface technology. The Maxi line includes all elements of an extrusion line with an upgrade of a fully automated drum winder. Ready-to-ship products are produced in just one line.

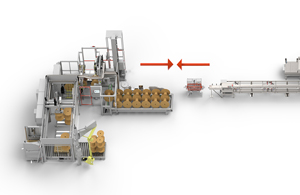

The system is interesting for all manufacturers of finished products who require automation up to the ready-to-ship pallet and brings many advantages. First: Work steps are saved and automated, as no spooling and unwinding is required between extrusion and final packaging. Secondly: Space is saved as all work steps are optimally coordinated and no spool storage is necessary. And third, production output is increased, reducing costs without increasing overall investment.

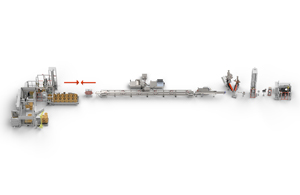

KURRE Systems supplies both the complete Maxi line or expands existing extrusion lines with the drum spooler section.

The Maxi line produces, coils, assembles and packages a wide variety of products and is individually adapted to customer requirements. Cable defects are detected, cut out and sorted out safely on a separate pallet. Good products are labeled, palletized, and, if required, securely wrapped for transport. The entire system is designed for user-friendliness and efficiency.

In the current version products with a diameter from 2.5 – 20 mm can be produced and automatically processed.

The Maxi line includes all elements of an extrusion line with an upgrade of a fully automated drum winder.

The line produces, coils, assembles and packages a wide variety of products and is individually adapted to customer requirements.

KURRE Systems supplies both the complete Maxi line or expands existing extrusion lines with the drum spooler section.