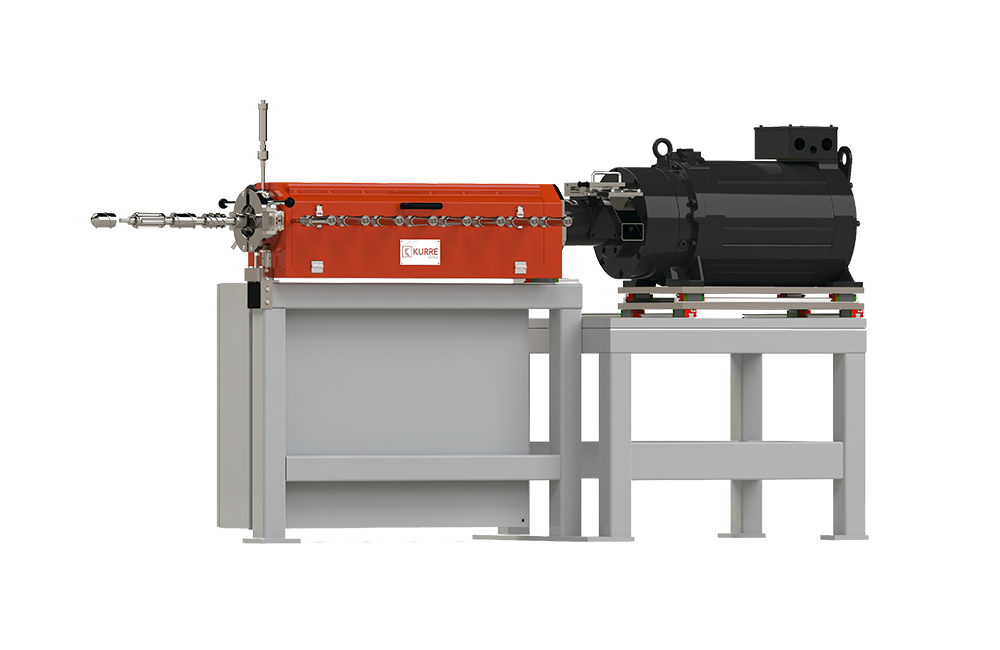

Laboratory extruder for customer-internal product engineering

KURRE Systems has further developed the laboratory extruder for customer-internal product engineering. The current model is used to simulate different screw designs. In the extrusion process, the nine sensors provide detailed data processing.

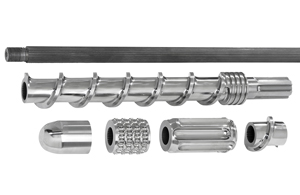

The quick-shifting system enables the motor to be pushed to the side, thus allowing flexible replacement of the feed bush. This enables a smooth test different groove geometries. Pressure and temperature measurements of individual or all barrel zones take place simultaneously. The laboratory extruder is also equipped with an analysis tool for optimum evaluation of process parameters and energy consumption. For example, when testing e.g. new polymers, the laboratory extruder provides more meaningful process values than a production extruder, enabling an easier verification of screw designs and material properties. The screw is easily adjustable to suit unknown materials. Likewise, compression flights, barrier flights or mixing and shear segments can be easily replaced.

The laboratory extruder plasticizes all common as well as new polymers, e.g. special materials such as PFA or PEEK with high-temperature applications up to 400 °C. KURRE Systems also offers all laboratory tests (including physical foaming) as an engineering service in its own technical center.

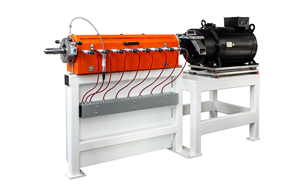

Laboratory extruder for customer-internal product engineering.

The screw can be individually adjusted for unknown materials in just a few steps.

KURRE Systems also offers all laboratory tests (including physical foaming) as an engineering service in its own technical center