NEW STANDARDS IN WINDING TECHNOLOGY

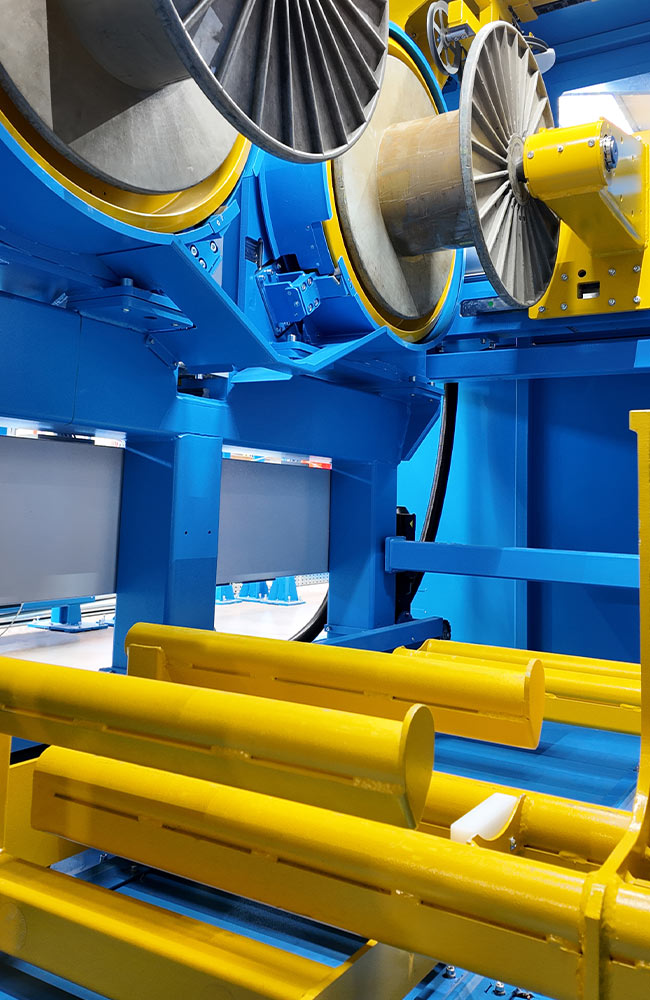

KURRE Spezialmaschinenbau GmbH, the parent company of SIEBE Engineering, has launched a new, state-of-the-art series machine, the VA-P-630, which sets new standards in the field of coil winding.

As a leading provider of innovative solutions in the field of machine and plant engineering, particularly in cable extrusion, the company has a comprehensive portfolio with a clear focus on quality, efficiency, and customer satisfaction. KURRE develops products that meet the requirements of modern industry.

The VA-P-630, originally developed in 2022 as a custom automatic winder, fills the gap left by the discon-tinuation of the popular Leimbach CD06. The further development of this model offers an ideal solution for modern production requirements and convinces with its versatility and efficiency.

Outstanding Performance and Flexibility

The VA-P-630 is capable of winding coils with a winding diameter starting at 315 mm at impressive speeds of up to 2000 meters per minute. The machine ensures automatic overlap, which significantly increases production efficiency. It is a valuable investment for companies, as it not only increases production capaci-ties in the conductor area but also guarantees consistently high product quality.

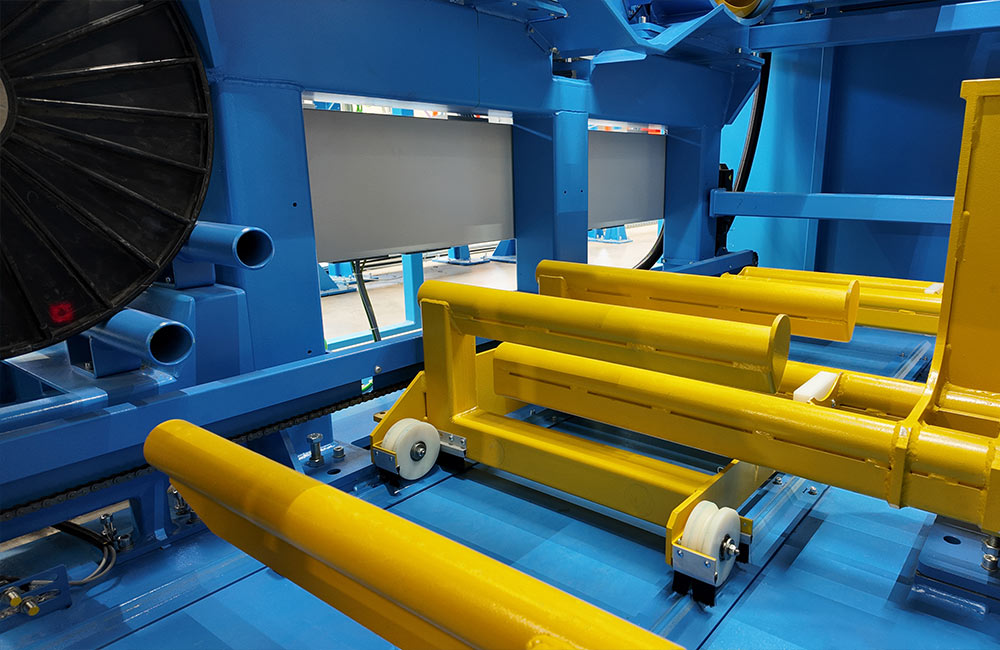

Thanks to the automated coil handling – including empty and full coil magazines – the entire winding pro-cess is seamlessly and efficiently executed. This enables fully automated production without the need for extensive manual intervention.

Versatile Options for Maximum Flexibility

A standout feature of the VA-P-630 is its flexibility. Unlike many competitors, this model can be equipped with additional options that enable an even wider range of applications. For example, the machine can process coils with a maximum weight of 500 kg, which significantly enhances production flexibility.

Another highlight is the tension control, which offers a range of at least 1:20, with a minimum tension of 3 N. Additionally, a tension monitoring and adjustment system can be integrated to allow for precise adapta-tion to different materials and winding requirements. All changes in tension are accurately documented, ensuring complete control and quality assurance throughout the production process.

Perfect Winding Results Thanks to Innovative Technology

The automatic edge correction, a proven feature from KURRE, ensures precise control of the winding pat-tern – particularly at switching points. This prevents the formation of peaks or valleys, even with very small products with a diameter of less than 1 mm. To further optimize the coil handling process, a chain con-veyor can be integrated instead of a ramp system. This provides a gentler handling of the coils and mini-mizes the risk of damage during transport.

Quality and Safety at the Highest Level

The VA-P-630 is equipped with all the necessary product certifications to enable the installation of measur-ing devices such as spark testers. This ensures that the produced coils meet the highest quality standards and eliminates the need for post-processing through rewinding. The integration of these safety and quality features makes the machine a reliable solution for demanding production processes.

The VA-P-630 as the Ideal Solution for Modern Companies

“With the VA-P-630, we offer our customers a powerful and versatile solution that not only meets but even exceeds the standard performance data,” explains Stefan Plaggenborg, Managing Director of KURRE Spe-zialmaschinenbau GmbH. “Our machine is aimed not only at customers who previously used the Leimbach CD06 but also at all companies looking to optimize their production processes.”

The VA-P-630 is now available and is ideal for companies seeking an efficient and flexible solution for coil winding. For more information and personalized consultation, interested parties can contact the experts at KURRE.