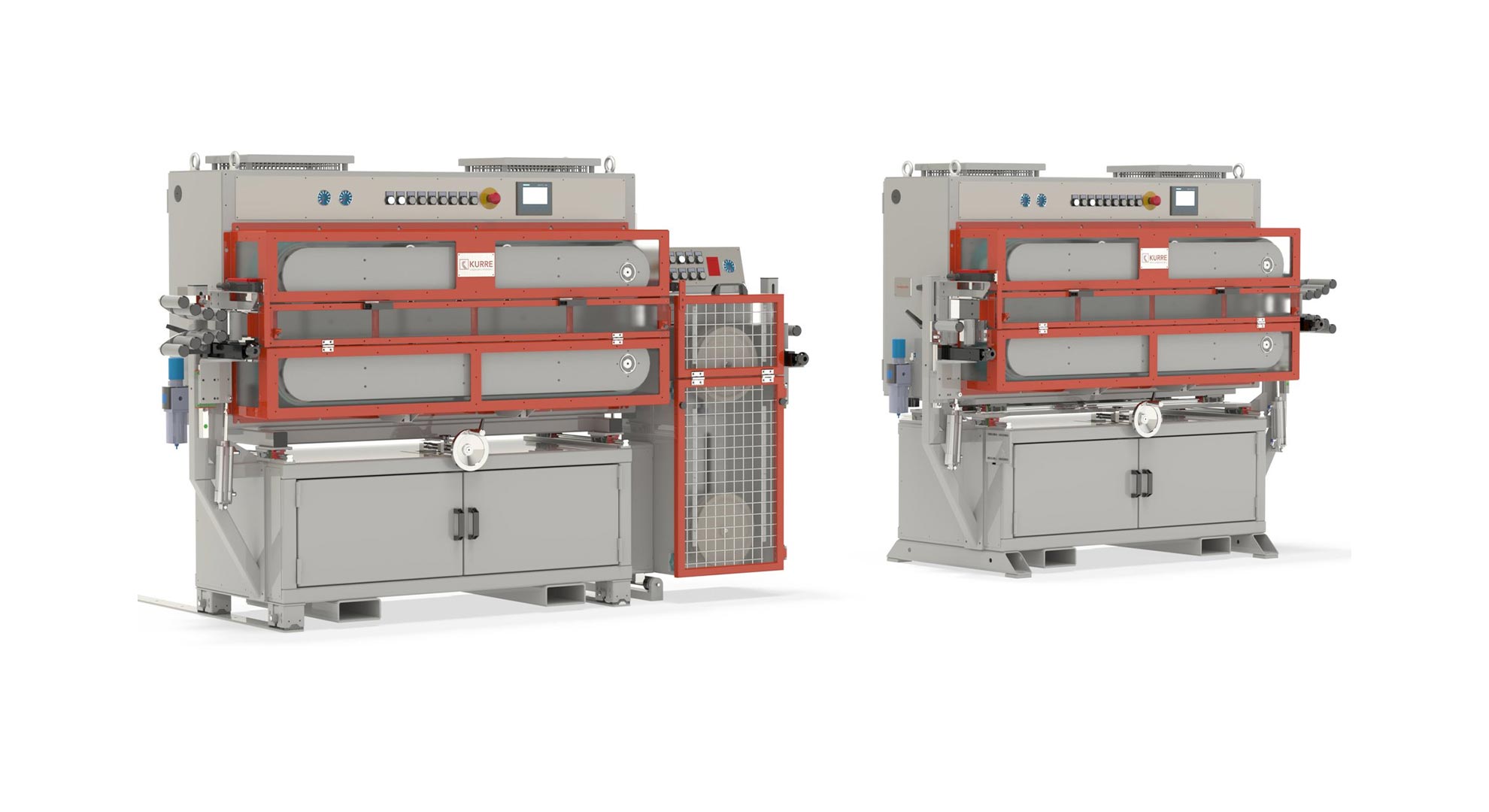

KURRE caterpillar – one machine, three modes

The currently developed caterpillar concept from KURRE offers three different possible user modes. The objective is clear: the widest possible range of applications.

The concept consists of two centered, almost identical caterpillars, each with 800 mm contact length, 2,000 N maximum tension force and an integrated dancer.

In the first operating mode only the pulling caterpillar with 100% speed control is used. The pushing caterpillar remains out of operation and is driven out of the line transversely by an integrated, very smooth-running rail system. The pulling caterpillar pulls the product through the extrusion with a speed setting of 0-100%. The required tension force is generated by the pay-off. The integrated tension force measurement system is used here as a pure display without further control function.

In the 2nd operating mode both caterpillars are used, whereby the push caterpillar is speed controlled from 0-100%, the pulling caterpillar is then readjusted via the integrated tension force measurement. The usable pulling force range is 100 N – 2,000 N.

In the 3rd operating mode an integrated dancer is activated at the push caterpillar. The pulling caterpillar is used speed controlled 0-100 %, the push caterpillar follows dancer-controlled with a tension force of 10-100 N. This allows the extrusion of products sensitive to tension forces at a very constant speed.

Both caterpillars are located within the same extrusion line approx. 30 m apart.

For products sensitive to bending, e.g. stranding or bandages, all guide rollers on both caterpillars can be moved vertically so that the product can be inserted into the caterpillars easily and without any bending when the guard is open and the belts are moved apart.

Also included is the belt cross adjustment, which is common for KURRE caterpillars. This prevents premature wear and tear as well as the run-in of the belts. In addition, cable production can be changed over very quickly from very thick to very thin products without causing slippage in the caterpillar.